Titanium (Ti) owing to its well-documented biomechanical properties, it is accepted as standard material for implant abutments.

The advantages of standard abutments are time efficiency in the overall treatment and therefore, shortening of the technical manufacturing time. Divergences between implants or malpositioned implants can be corrected with angled standard abutments.

They are available with a variety of collar heights to achieve optimal emergence from shallow or deep gingival wells, in order to obtain outstanding esthetic results.

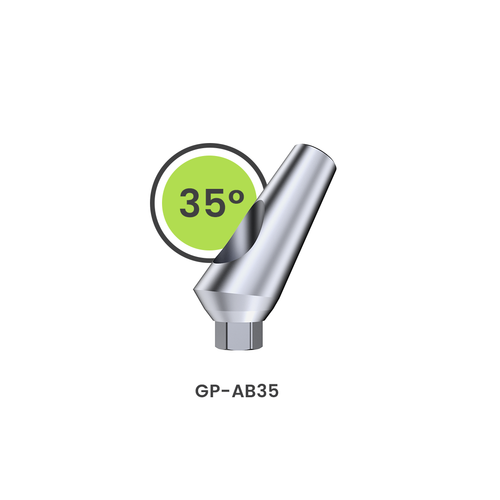

These abutments are available with angles of 15° and 25° degrees.

Angulated abutments are used when dental implants are not placed parallel to adjacent teeth or contiguous implants, the clinician can use angled abutments to achieve proper restorative contours

When to use

- Cement- retained single crowns or bridges

- Endosseous implants placed at unfavorable angles may be restored with angled abutments without compromising function or esthetics.

- To compensate for the divergence of seated implants.

How to use

- Treatment planning with radiograph

- Try the abutment on implant intraorally or on working model.

- The abutment must be carefully hand-tightened into the lab analog with an abutment retaining screw.

- Lab process

- When cast is ready, it is then fixed to the implant by the recommended abutment screw and torque is dictated by manufacturer’s instructions (30 NCM)

Clinical advantages

- Provides better prosthetic suppor

- Excellent biocompatibility

- Good strength

- Facilitate paralleling nonaligned implants, therefore making prosthesis fabrication easier.

- These abutments can aid the clinician in avoiding anatomical structures when placing the implants. In addition, the use of angled abutments can reduce treatment time, fees and the need to perform guided bone regeneration procedures.