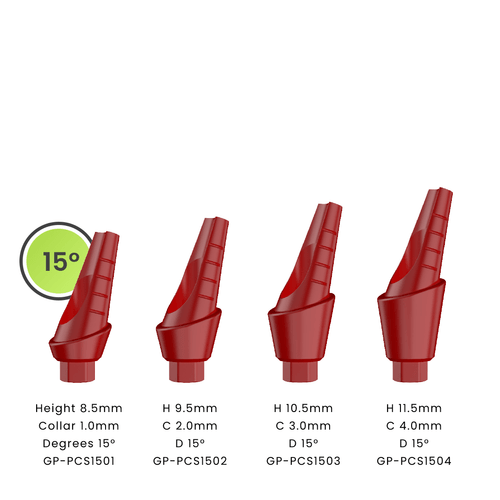

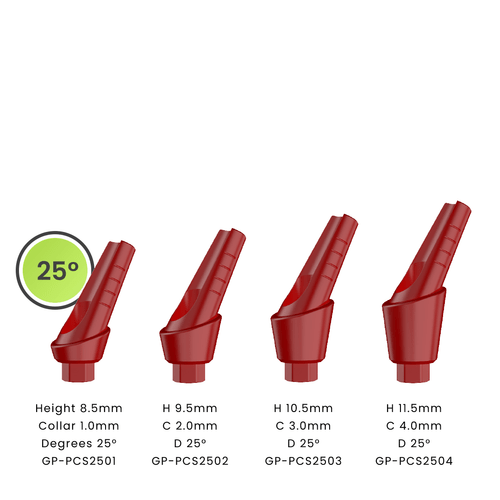

CASTABLE ABUTMENTS

Plastic castable abutments are intended for use by the technician for simple casting of custom-made abutments for constructing the prosthetic restoration. Use this technique for a lab-fabricated, custom, screw-retained crown, or cement retained. The custom crown can complement soft tissue contour, height and also can correct angulation.

When to use

- Single and multiple-unit restorations

- For aesthetic restorations when tissue is limited

- Minimum inter-arch space of 4 mm

- Screw and cement retained restorations

- Mild or moderate implant malposition

How to use

- Make an implant level impression

- Lab process

- Pour the working model

- Seat, mark, and modify the abutment (seat the selected custom castable abutment onto the implant analog in the working model)

- Wax the custom abutment

- Sprue, invest and cast the abutment

- Divest, fit, and finish the abutment

- Apply the porcelain

- Seat the final restoration

- Check and modify the restoration and take radiograph along the long axis of the implant to ensure that the crown is seated completely in the hex of the implant.

- Tighten the abutment and screw (do not exceed 20 NCM, we recommend 15-20 NCM)

- Fill the screw and access channel

Clinical advantages

- It is easier to correct the angulation of implants

- The final restorations are manufactured to the patients exact gingival architecture, achieving an optimal emergence profile and a more esthetically pleasing outcome.

- Clinical alternative to mild or moderate implant malposition