Introducing GP Implants LTD's Latest Innovation - The DLC Step&Stop Kit Our cutting-edge drill kit combines three of the most important advancements in implant drilling technology. Designed to improve accuracy, stability, and efficiency in implant placement procedures, our DLC Step&Stop kit provides oral surgeons and all dentists who place dental implants with the ultimate solution.

With a monolithic design and pre-integrated stopper, our drills offer perfect balance and eliminate the risk of over-drilling mistakes. The stepped shape of the drills is specifically designed to mimic the geometry of conical taper implants, ensuring a fast and accurate drilling process. Our DLC coating minimizes friction and heat generation, providing a longer lifespan for the drills.

Each drill in the kit is matched to the length of the implant, ensuring maximal stability and minimal over-drilling. The high contrast and clear depth markings make our DLC Step&Stop kit the perfect choice for both novice and experienced professionals. These drills are compatible with GP Implants LTD's Spiral or Conical Implants, as well as other comparable systems in the market.

Key Benefits of GP Implants LTD's DLC Step&Stop Kit: • Minimizes cutting resistance and heat generation with DLC coating • Provides precise depth control, reducing the need for visualization • Improves implant preparation positioning in relation to adjacent teeth • Enhances depth management in flap or flapless surgeries • Achieves a long and stable tool life with the DLC coating and cutting-edge design • Offers improved visibility in the operational field • Perfectly balanced and easy to clean and sterilize due to monolithic design • Includes a premium Italian plastic autoclave-ready box • CE/FDA certified and made in Israel.

Get the DLC Step&Stop Kit now with your purchase of 60 implants! Experience the benefits of this advanced drill kit and take your implant services to the next level.

SSI is the optimal solution for immediate implantation and immediate loading. The SSI dental implant has exceptional self-drilling capabilities and a unique spiral body design which enables it to change its position during placement and obtain very high primary stability even in very complicated clinical cases.

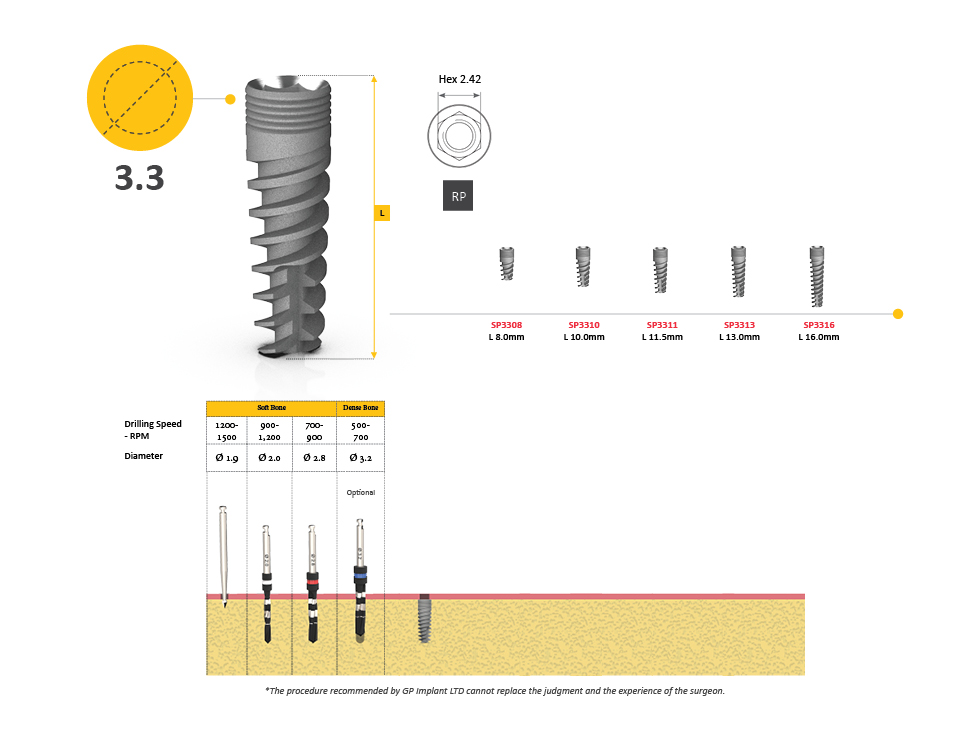

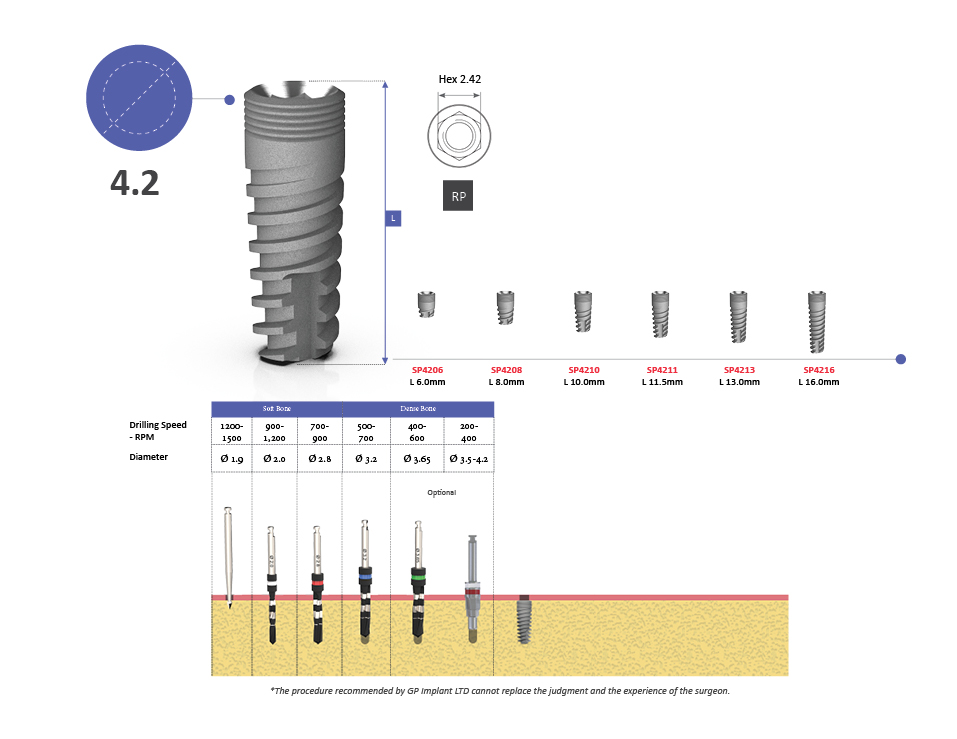

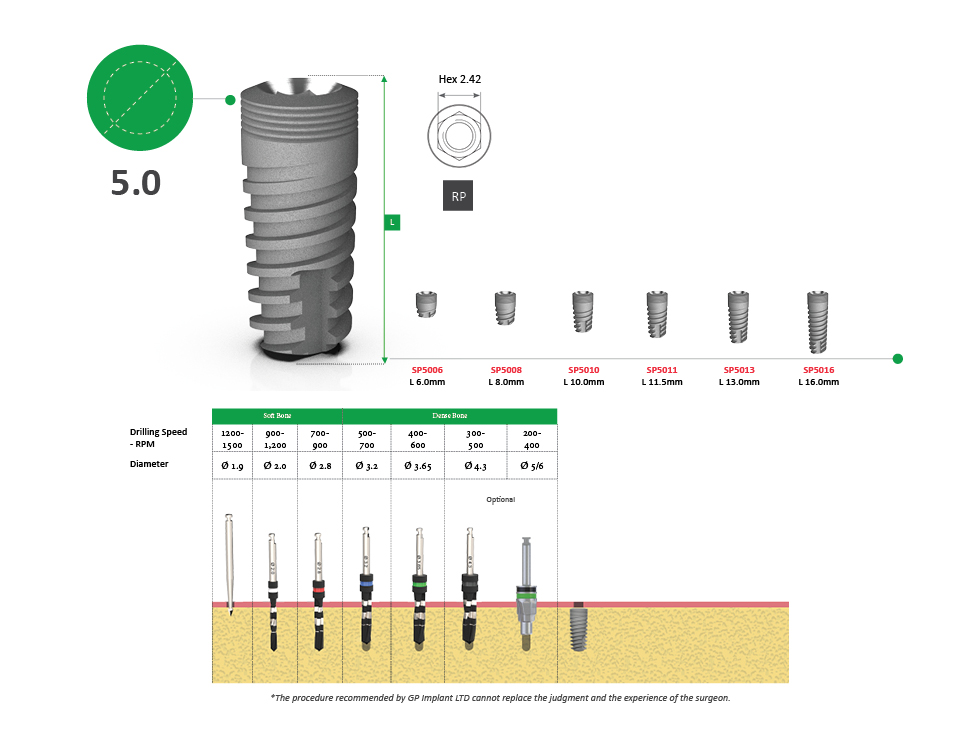

Drilling Protocol

Drill sequence by bone type -

An additional 1 mm must be added to the length of the drill to account for the angled cutting tip.

D-I, D-II Dense bone considerations -

Countersink should be used if the standard dense bone protocol is not sufficient to fully seat the implant without exceeding the recommended maximum insertion torque of max. 60Ncm for implant Ø3.75mm and above. Do not exceed max. 45Ncm for implants diameter lower than 3.75mm.