SSI is the optimal solution for immediate implantation and immediate loading. The SSI dental implant has exceptional self-drilling capabilities and a unique spiral body design which enables it to change its position during placement and obtain very high primary stability even in very complicated clinical cases.

| 1 Micron level (microgap) between the implant platform and the abutment is kept to an absolute minimum. |

| Rough surface on the top. Threads reaching the top of the implant. Advantage: Decreasing the crestal stress |

| Tapered body and code. V Shape Body Design. Advantage: Very Easy Implant Insertion. |

| Expanding tapered implant body with double-thread self tapping design condenses bone gradually to enhance primary stability. |

| Rounded apex improves the ease of insertion and allowing mild direction refinement during the initial stages of insertion |

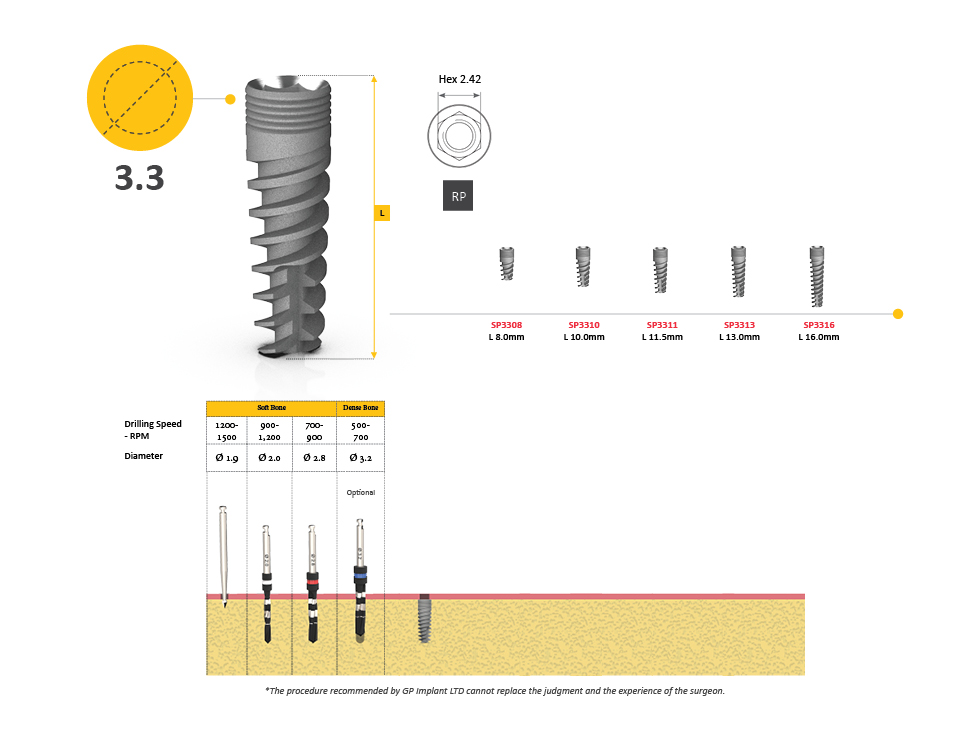

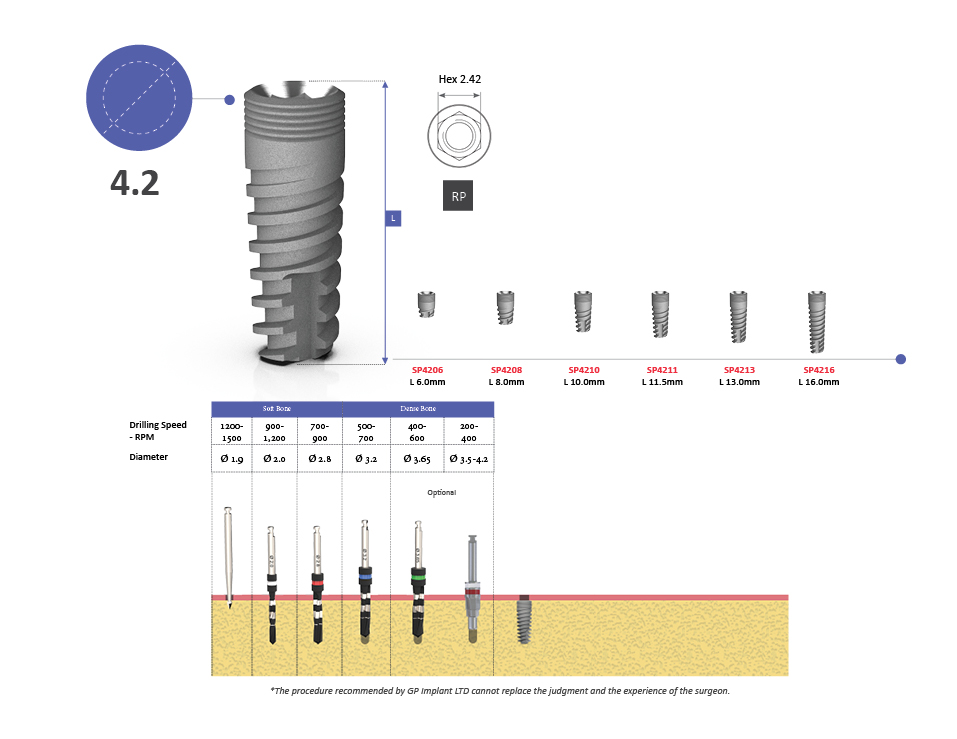

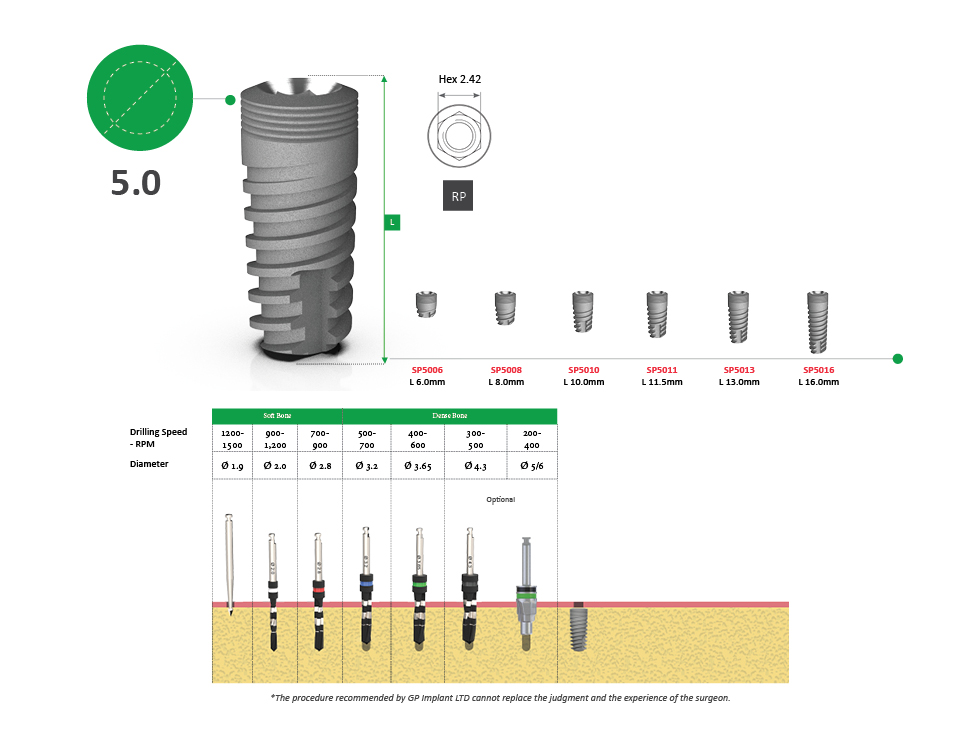

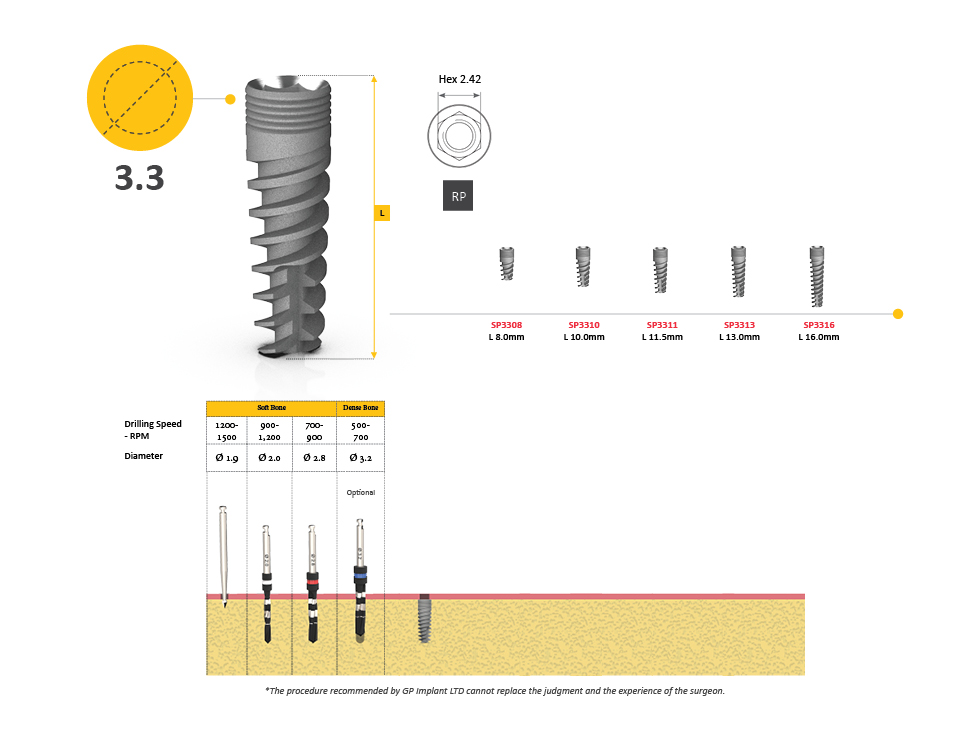

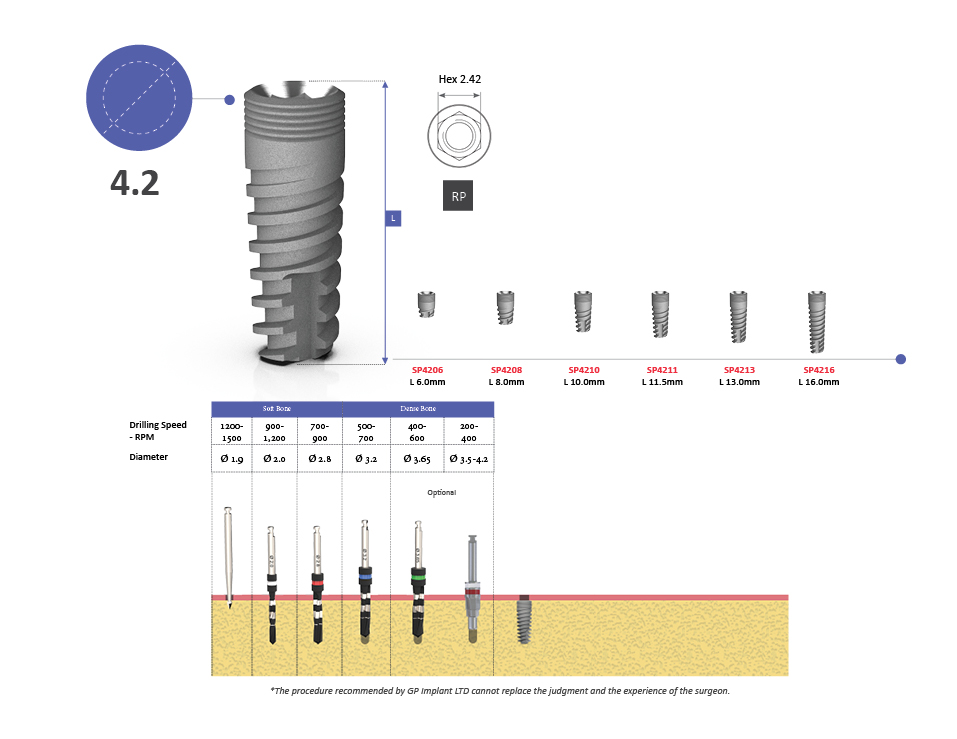

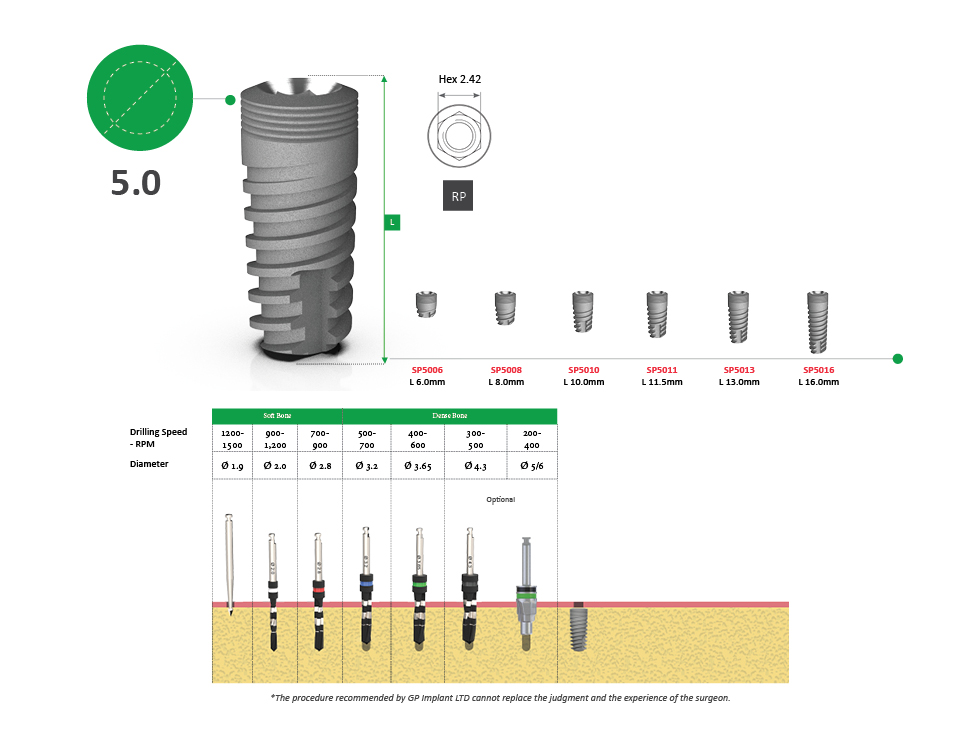

Drilling Protocol

Drill sequence by bone type -

An additional 1 mm must be added to the length of the drill to account for the angled cutting tip.

D-I, D-II Dense bone considerations -

Countersink should be used if the standard dense bone protocol is not sufficient to fully seat the implant without exceeding the recommended maximum insertion torque of max. 60Ncm for implant Ø3.75mm and above. Do not exceed max. 45Ncm for implants diameter lower than 3.75mm.

GP Implants exercises great care and effort in maintaining the superior quality of its products.

All GP Implants products are guaranteed to be free from defects in material and workmanship.

However, should a customer find fault with any GP Implants products after using it according to the directions, the defective product will be replaced free of charge.

Warning: Products should be used by licensed dentists only.